Deck Guns and Aerial Monitors

Introduction

High volume master stream discharge devices have many names. Deck gun, water cannon, deluge, monitor, ladder pipe and others. This Buyer’s Guide will review the important features, benefits, and safety considerations of these high flow devices that can be found on pumpers and aerial devices. In today’s fire service, many times these high flow rates of water are required for quick knockdown of moderate sized fires, or containment of very large fires in a defensive or “surround and drown” operation.

This Buyer’s Guide will use the terms Deck Gun to refer to pumper-mounted master streams and Aerial Monitor to refer to permanently mounted master streams on aerial devices such as ladders, platforms, articulating and telescoping water towers that provide elevated master streams.

This Buyer’s Guide will present high flow master stream devices in two general use categories: Pumper and Aerial. While this Buyer’s Guide will provide insight into the features and benefits offered with various product types that are provided by several manufacturers, some features may be proprietary to a single manufacturer. This Buyer’s Guide does not endorse any manufacturers’ products. Work with FAMA member apparatus and equipment manufacturers and their dealers to understand what options are available.

Contents

Deck Guns

MANUALLY OPERATED

Deck guns are the large master stream devices found on many pumpers, most often mounted near the center of the apparatus, above the pump. Deck guns can be manually operated by personnel on top of the apparatus. Manual deck guns are the least expensive but require a dedicated operator to be in a position on top of the apparatus.

MANUALLY OPERATED (Cont.)

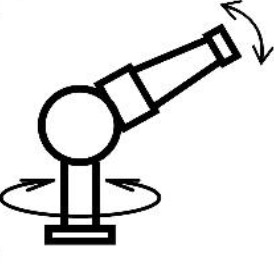

Standard features of most manual deck guns include the ability to rotate the unit horizontally 360° and control the elevation vertically, usually from 45° below horizontal to 90° above horizontal. These movements can be done by means of tiller bars, handles, and hand cranks. Some deck guns have a crank for one operation (i.e., elevation) and a tiller bar or handle for the other operation (i.e., rotation). Locks for elevation and rotation travel are common when tiller bars or handles are utilized. When hand cranks are provided, they are self-locking by design, so travel locks are not required.

Unique features and options to consider

Portable Ground Base

Some manual deck guns are quickly and easily removeable from their deck pipe so they can be connected to a portable ground base and used as a ground monitor that is fed by one or more hoses. This type of deck gun will have an elevation travel stop at about 35° above horizontal. When mounted to the apparatus, the travel stop can be overridden, usually by pulling a spring-loaded pin, to allow aiming of the stream further downward from the top of the apparatus. When the deck gun is placed on the portable ground base, the nozzle elevation should be brought up so the spring-loaded pin can return the nozzle to the locked position above 35°. The travel stop prevents the stream from being pointed any further downward, which if overridden, reduces stability of the portable ground base, Portable monitor bases include a tie-down strap to attach the portable base to a substantial object to limit the movement of the device if it loses stability. Some portable bases have a safety device to reduce the flow and reaction force should the ground base lose stability.

Many agencies are opting for a non-removable deck gun and using dedicated portable quick-attack ground monitors. This eliminates the need to climb to the top of the truck to remove the deck gun monitor top and hand it down for connection on the portable base.

Unique features and options to consider (Cont.)

Cantilever Nozzle Discharge

Some manufacturers offer deck guns that allow the nozzle discharge portion of the deck gun to be raised up higher and locked to allow the stream to clear obstacles on top of the apparatus such as hose reels, generators, light bars, and raised cab roofs.

Some manufacturers offer a portable ground base for this style monitor. Using it in the lowered position provides the most stability when on the ground base.

Unique features and options to consider (Cont.)

Telescoping Waterway

Another option to raise the entire deck gun is by means of a telescoping waterway. These can be manually, electrically, or pneumatically operated. Telescoping waterways have a substantial portion of the unit located below the deck area, where the deck gun is normally stowed for apparatus travel. Units are offered with either 12” or 18” extension of the waterway, to allow clearance of the stream over obstacles on the top of the apparatus. Manual deck guns can be integrated with manual, electric or pneumatic telescoping waterway units. Electric or pneumatic units decrease the risk of lifting injuries compared to manually raised units. One consideration of using a manual telescoping waterway is the weight of the monitor that will be lifted by the operator when telescoping the waterway.

Unique features and options to consider (Cont.)

Deck Pipe Extension

Some manufacturers offer an extension pipe that is placed between the deck gun discharge pipe and the quick disconnect type deck gun when additional height is needed. This increases the operating height of the deck gun to allow clearance over obstacles on top of the apparatus. It should be removed before the apparatus travels to prevent damage to the deck gun and anything it may contact.

REMOTELY OPERATED

Deck guns can also be controlled remotely, most often electrically, with controls mounted on the pump operator’s panel, or on a tethered cable, or wirelessly from locations several hundred feet from the deck gun device itself. Remotely operated deck guns will have an increased cost compared to manually operated deck guns.

Operating remotely eliminates the need to have a dedicated deck gun operator on top of the apparatus. Having a tethered or wireless remote control can provide for better viewing of the deck gun and water stream, allowing for improved aiming of the stream to the target area where the water application is desired. Many times, multiple operator controls can be used on a single monitor.

Electric remote controls will include at a minimum, horizontal (left/right), vertical (up/down), and stream pattern (fog/straight stream) adjustments using buttons, switches, or touch screen. Other controls may include valve (open/close), stow (park), deploy, raise/lower if a telescoping or cantilever waterway is installed, and oscillate. Some controls may also include a screen to view various parameters of the operation such as valve position, monitor position, voltage, multiple monitor control selection and more.

Electrically operated deck guns typically are not removeable to use on a ground base. Electric deck guns are available that cantilever remotely to raise above the apparatus’ upper obstacles. Electric deck guns are usually heavier than their manual counterparts and if a telescoping waterway is used, it is recommended to use an electrically or pneumatically operated telescoping waterway.

Remotely operated deck guns usually allow horizontal travel of 360°, however, that may not be continuous as they have travel stops to limit rotation to prevent tangling or damage of wiring. Elevation travel is similar to manually operated monitors at 45° below horizontal and 90° above horizontal.

DECK GUN LOCATION

The location above the pump aids in limiting the amount of plumbing needed from the pump to the deck gun. Many midship style pumps have a large discharge port at the top of the pump to be used for the deck gun. Using other discharges may create long piping runs or piping with many elbows possibly limiting the flow to the deck gun or requiring more pump discharge pressure to achieve a high flow, due to the higher friction loss.

Deck guns can be located in other places on the apparatus such as above the rear corners of the body compartments, to the left or right side above the pump are also common locations. Consider what options are available from your FAMA member apparatus manufacturer and how they will be utilized by your agency.

FLOW RATES

Deck guns typically have flow rates from 500-2000 gpm. The most common are 1250 gpm and 1500 gpm.

Some specialized apparatus may have deck guns with higher flows, 2500-8000 gpm or more, and may have multiple deck guns. These are typically used for industrial firefighting applications.

NOZZLES

Nozzles for deck guns can be combination (adjustable fog/straight stream), smooth bore, or smooth bore stacked tips.

Combination nozzles can be single (fixed) flow, selectable flow, or automatic variable flow constant pressure. Stream can be adjusted manually for manual deck guns and electrically for electric remote deck guns. Stream adjustment is from straight stream to a wide fog pattern.

Smooth bore nozzles offer a fixed flow rate at a certain pressure, usually 80 psi for deck guns. Stacked tips normally are three or four different smooth bore tips that thread to each other to offer various fixed flow rates, also usually rated at 80 psi. Stream straightener or stream shapers are usually installed behind the smooth bore or stacked tip to improve the straight stream reach. These devices have internal fins or vanes to help straighten the stream.

Some manufacturers offer devices to provide a spray pattern and smooth bore straight stream from a single device using a simple adjustment of the device either manually or electrically.

Some fire departments install a valve between the deck gun outlet and the nozzle to provide on/off control at the manually controlled deck gun.

CHOOSING THE RIGHT SIZE DECK GUN

Understanding the agency’s normal operating conditions, such as typical water supply operations (drafting, relay pumping, and hydrants), operating locations that would require high flow water streams, and pump capacity of the apparatus are useful when determining what flow rate deck gun to purchase. Consider future changes to your water supply capabilities and future high flow locations in your response area as the apparatus you are purchasing now will likely be in service for many years to come.

Simply matching the deck gun maximum flow rating with the capacity rating of the pump provides a sound base line. Example, if the pump is rated at 1250 gpm, choose a deck gun that will flow up to 1250 gpm.

However, if water supply capability is very limited a lower flow rate deck gun might be considered. If normally utilizing the deck gun with tank water, realize that NFPA minimum tank-to-pump flow rate is 250 gpm for tank capacity of less than 500 gallons and 500 gpm if the tank capacity is 500 gallons or greater. Larger and/or multiple tank-to-pump valves and piping may be specified to achieve higher flows from the tank.

If you normally draft or use relay pumping for your water supply, you might base your deck gun flow on the volume of sustained gpm that can be achieved by these supply means.

Inversely, if the pumper typically uses a pressurized hydrant system that is reliable and capable of high flows, then a higher flowing deck gun compared to the pump capacity rating can be chosen. Pump capacity ratings are determined at draft, so providing water from a pressurized source can increase the pump’s flow capabilities substantially and easily provide higher flows to the deck gun.

In general, the higher the flow, the more reach the stream will have.

Aerial Monitors

Aerial monitors are very much like deck guns but have unique characteristics. Aerial devices can be divided into 3 categories; Ladders; Platforms; Water Towers. Monitors on each of these devices vary with their configurations and usage.

AERIAL LADDERS

Aerial ladder monitors are most often electrically controlled.

Pinnable Waterway

Straight stick ladders may have a pre-piped waterway feeding a monitor. The monitor is usually mounted so that it can be quickly positioned and locked (pinned) to the outermost fly section so the ladder can be used as an elevated stream device. This is often referred to as the water tower mode.

Or the monitor can be positioned and locked (pinned) to the intermediate ladder section where it remains away from the outermost fly section tip so the ladder may be used for rescue. This keeps the monitor away from the tip of the ladder to provide more clearance at the ladder tip and to protect the monitor from damage. This is called the rescue mode. The monitor can still flow while pinned to the intermediate ladder section. What is described here is referred to as a pinnable waterway.

Horizontal travel of the monitor is usually limited to 90° left and right or less, to avoid hitting the ladder and limiting the side loading of the ladder due to the stream’s reaction force. Vertical travel is referenced to the inlet flange of the monitor and is usually 45° below horizontal to 90° above (parallel to the ladder), and up to 30° of additional upward travel when in water tower mode.

When in water tower mode, most ladder monitors offer the ability to point the stream in an upward angle, which can allow the ladder to be pointed horizontally or downward, and the monitor stream can be pointed more upward. This ability is locked out when the pinnable waterway is in the rescue mode, to prevent the stream from shooting through the rungs of the ladder and to reduce interference between the monitor and ladder components.

NFPA requires a minimum of 1000 gpm nozzle to be provided if the ladder has a pre-piped waterway. Maximum flow rates are determined by the ladder manufacturer and consider many factors including, but not limited to the flow rate of the nozzle, elevation, extension, and the number of personnel on the ladder. Most ladders monitors are rated at 1500 gpm or less. Consult the FAMA member apparatus manufacturers for options available.

Ladder Monitor Controls

Controls for the ladder monitor usually include a simple set of three toggle switches which is used at the tip of the ladder to control horizontal, vertical, and nozzle functions should an operator be present at the tip of the ladder.

Per NFPA controls at the ladder turntable at the base of the ladder are required and shall override any other control. The controls may be toggle switches or a panel type control to allow the basic functions and additional functions such as stow, deploy, and oscillate. Wireless controls for the monitor are becoming more popular. They allow control of the monitor from remote locations which may have a better vantage point of where the stream is hitting. This also allows the monitor to be operated if no one is on the ladder.

The controls at the ladder turntable will always be the master control and override any operation of the monitor being done at the tip of the ladder. This is to allow operation of the controls by the operator at the turntable in the event the personnel at the ladder tip become incapacitated or are not present.

Ladder Monitor Controls (Cont.)

Panel mount and wireless controls are similar to those used for Pumper Deck Guns. (see above)

AERIAL PLATFORMS

Aerial platforms have a “basket” on the end of the ladder providing a larger platform for one or more personnel to work from.

Manufacturers of aerial platform apparatus offer single or dual monitors. The monitor(s) may be mounted on the front, sides, or under the basket. Monitors may be manual, or electrically operated. When dual monitors are provided one may be electric and the other manual, or both electric, or both manual. Having electric remote monitor(s) allows control of the monitor without the need for personnel in the basket.

AERIAL PLATFORMS (Cont.)

Controls are typically tiller bar or hand crank for manual monitors. Electric monitors will have controls operable in the basket and at the turntable. Wireless controllers are also offered which may allow the operator to be in a position to see where the stream is hitting. The controls at the turntable shall override all other controls. The turntable controls are similar to those used on Aerial Ladders. (see above)

Monitor travel shall be a minimum of 45° left and right of center and 45° above and below horizontal. A slow-operating valve shall be provided at the base of the monitor.

WATER TOWER

A water tower is an articulating and/or telescoping boom device that is used as an elevated stream application device. A water tower shall provide an elevated water stream capable of delivering a minimum stream of 1000 gpm at 100 psi. Water towers may have electrically or hydraulically operated monitors. The monitor/nozzle shall operate 45° either side of the centerline of the boom and at least 30° above and 135 degrees below the centerline of the boom.

AERIAL MONITOR VALVES AND HOSE CONNECTIONS

A valve at the base of the monitor is required for aerial platforms and is also available for aerial ladders. These valves can be a butterfly style valve, or a ball style valve. Typically, a butterfly valve will introduce additional friction loss and turbulence which can affect the flow rate and stream reach because the blade of the valve is in the middle of the waterway when the valve is in the open position. A ball style valve will provide a more open waterway, reducing pressure loss and turbulence.

The monitor valves can be manually or electrically controlled.

Hose connections, if provided, shall be 2-1/2” minimum on an aerial platform. These connections usually have manual valves to control the flow to the 2-1/2” outlet.

Hose connections can be used for various tasks, including using the aerial as an outside standpipe connection to provide a water hose connection at upper levels of a structure using the aerial’s waterway. Also, attack hose lines may be attached to a hose connection for hand line firefighting operations from the aerial platform.

Hose connections can be piped in as part of the water delivery system. Some manufacturers have integrated the monitor base valve and the hose connections into a single unit. This provides for simpler installation by the aerial manufacturer, easier maintenance and reconfiguration if needed during the life of the apparatus. Other options are available such as automatic drains and pressure relief valves installed in the same body as the monitor valve.

Summary

Deck guns and aerial monitors can provide hard-hitting, high flow streams when needed. Understanding the options available from the FAMA Member Apparatus Manufacturers, Equipment Manufacturers, and their Dealers will assist in making educated decisions on what to specify to get the most out of your next apparatus.

Appendix

SAFETY

When flowing high volumes of water, there are several safety factors that need to be considered. While manufacturers have provided many safety features and detailed user manuals on their products, it is ultimately the Authority Having Jurisdiction (AHJ) that is responsible for having safe operational procedures in place, and to provide training on those procedures and the proper use of the equipment as recommended by the manufacturers. The operator of the equipment also shares a responsibility to operate the equipment with due regard to themselves, other public safety personnel, and public persons and property when flowing high volumes of water from deck guns and aerial monitors. This includes using the safety features of the products and not circumventing them. High flow water streams hit with extreme force that can cause injury and damage property. Continued application of large volumes of water can contribute to structural collapse due to the weight of the applied water. Appropriate fall protection devices should be worn when operating from aerial devices and from the top of apparatus.

NFPA

NFPA (National Fire Protection Association) 1900 Standard makes no reference that a pumper shall be required to have a deck gun.

Aerial ladders are not required to have a pre-piped waterway. If a pre-piped waterway is provided, then a permanently attached monitor shall be provided. It must be capable of flowing 1000 gpm at 100 psi at full elevation and extension.

NFPA does dictate that aerial platforms of 110 feet or less must have a permanent water delivery system installed. One or more permanently mounted monitors and nozzles shall be installed capable of discharging 1000 gpm at 100 psi with the platform at rated vertical height.

Water towers shall have a minimum flow rate of 1000 gpm at 100 psi.

Use of Images

Reference the images used in this guide: