Roll-Up Compartment Doors

FAMA BUYER’S GUIDE TC054 Roll-Up Compartment Doors

Roll-Up Compartment Doors

Prepared by the FAMA Body Subcommittee

This guide does not endorse any manufacturer or product

Contents

Introduction

Compartment doors are an important part of each fire apparatus and there are many factors to consider when deciding the type of doors and the features that would be best for a department and a given application.

This guide is intended to provide fire service personnel with information about the various types of compartment doors available for fire apparatus and help in making good judgements with specifying apparatus.

As with any engineered system design, there are pros and cons to each configuration and not all are represented here. It is the responsibility of the purchaser to determine what best meets their needs and to specify this information to prospective apparatus bidders, sellers, and manufacturers.

As technology is continually evolving, this guide is presented as a general information and educational piece. The various equipment and options presented may not be available from every manufacturer, and some may be mutually exclusive.

For more information, contact the FAMA Member door and/or apparatus manufacturers listed at www.fama.org.

INDUSTRY STANDARDS

The National Fire Protection Association Standards define voluntary minimum standards for automotive fire apparatus. The two most widely used Standards are:

NFPA 1901®, Standard for Automotive Fire Apparatus

NFPA 1906®, Standard for Wildland Fire Apparatus

The current editions should be referenced when specifying new apparatus. www.nfpa.org.

Within these Standards, compartment doors in general are not typically referenced. However, there are specific components of a door system that are required and for which NFPA specifications are explicit. Door Ajar warning systems are one such component.

In Canada, ULC S515 Standard for Automobile Fire Fighting Apparatus is the accepted standard to reference.

Overview

It is essential to identify the overall requirements of the fire apparatus before determining the type of compartment doors and the features that will best suit your department’s needs. Once you have done so, and with the help of this guide you will be able to evaluate the following features to configure compartment doors that will best suit your department and your apparatus:

- Door type,

- Door sizing,

- Door locks,

- Door seals,

- Door finishes,

- Door Features including Door Ajar Switches, Integrated Compartment Lighting, Pull Straps, Drip trays

Door Type

There are essentially two types of doors; Panel and Roll-Up doors.

Panel Doors

Panel doors have been around for many years and are made up of traditional hinged panels that swing out, up or down. Typically, panel doors are manufactured by the apparatus builder. They are configured in either single or double doors to fill an opening and are usually equipped with a single or double point latching system that can also be key locking.

Roll-Up Doors

Roll-up doors have been in use in North America since the late 1980’s and are typically designed to roll into a door coil at the top of the opening. Since the year 2000, roll-up doors have become popular for most applications and are typically produced by companies who focus on door design and manufacture.

Since their introduction, roll-up doors have seen a number of innovations to accommodate an ever-increasing desire for larger compartments. Roll-up doors also represent the majority of surface area on a body and are one of the few components utilized on every single call during the life of the apparatus.

This Guide will help to identify the key features that will help ensure effective and long-term service of roll-up compartment doors.

Door Components

A typical Roll-Up door consists of the following components:

Door Curtain

- Door Curtain – including the extruded aluminum slats, bottom rail (bottom panel), latching system and, if desired, the locking system,

Balancer

- Balancer – the spring-loaded counterbalance that assists with opening the door and keeps it in the raised position,

Side Frames

- Side Frames – the extruded aluminum door track that extends beyond the compartment edge to provide a trim section to frame the compartment. Side Frames also secure the side seals and can, in some cases, hold the integrated compartment lighting

Top Gutter

- Top Gutter – an aluminum extrusion that closes off the top of the doorway,

Sill Plate

- Sill Plate – an aluminum extrusion that trims and protects the bottom edge of the compartment from equipment damaging the edge of the apparatus. This feature can also include a waterstop to help minimize water ingression at the bottom of the compartment.

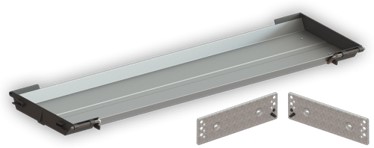

Balancer Plates

- Balancer Plates – mounting plates that support the balancer,

Door Ajar Switch

- Door Ajar Switch – a device that senses if the door is closed and turn on the compartment lighting,

Pull Strap

- Pull Strap – to assist in pulling down on the door to close

Drip Trays

- Drip Trays – to keep compartment contents safe from moisture dripping from the door surface.

Door Size

Doors should be sized to allow convenient access, removal and replacement of equipment that will be contained in any given compartment.

As an example, you will want to ensure that backboards are stored in a compartment with a clear opening height that suits reaching for, removing and replacing the backboard without excessive bending, lifting, twisting of your body or manipulating of the backboard.

There are practical limitations to how narrow, wide, short or tall a door can be and still work effectively. If you have an unusual configuration, it is recommended that you consult with manufacturers to ensure the configuration is realistic.

Door Locks

Increasingly, compartments are used to store expensive equipment or products, such as medications, that must be controlled. The Door Lock is the mechanism that provides security against theft.

Door locking options are available in many forms from single point cams to complex powered locking systems. For most compartment configurations and uses, a two-point key operated locking system will be the most cost effective and reliable.

POWER LOCKS

In situations where secure access is required and where the convenience of an electrical locking system can be justified, the powered locking system will allow remote access via cab mounted switch, key fob remote or other activation technologies. Where a powered locking system is desired, check with the door manufacturer to ensure the system has a secure manual over-ride in the event of a power or mechanical failure.

KEY STYLE

Many of the most common keys used in the fire service are single bitted. Meaning, the key has a shaped edge on one side only and the key can only be inserted into the lock cylinder in one orientation. Double bitted keys have a symmetrically shaped edge on both sides. Double bitted keys and cylinders are typically easier to operate, because the key can be inserted in either orientation, and they are more secure. Most automotive keys are double bitted.

KEY CYLINDERS

Long term operation of a key cylinder will benefit greatly if the cylinder is equipped with a “shutter” to prevent moisture, dirt and corrosive chemicals from accumulating in the interior of the cylinder.

Consideration should be given to the benefits of having a key sequence that is common to other departments in the fire service versus the benefit of having a key sequence that is less common and therefore, more secure.

Door Seals

Door seals are an integral component of the overall system to manage the ingression of water and debris. Seals will be located around the perimeter of the door including the underside of the bottom panel, side seals, top gutter and in between the door slats themselves.

It is important to note that there is no such thing as a waterproof roll-up door. Proper installation combined with the options selected can minimize water ingression. However, water and debris that collect on the exterior surface of the door will be drawn into the compartment when the door is coiling up as it opens. There are two basic options. Either a secondary seal can be used to “wipe” the surface of the door (which can eventually lead to surface abrasion or paint wear) or a drip shield can be used to collect and direct water introduced by the door’s exterior. More on this topic in the section titled Drip Trays.

All seals should be manufactured using materials that will withstand the temperature and chemical exposures associated with fire apparatus operations.

SIDE SEALS

Side Seals are typically plastic extrusions that are retained by the Side Frames and close off the side of the opening. Consistent Side Seal contact with the door surface is critical to meet the performance requirement of minimizing ingression.

For doors specified with painted surfaces, seals will eventually wear through the coating where the seals contact the door curtain. This wear is inevitable unless secondary measures are taken. It is suggested that this topic be explored with the apparatus manufacturer at the time of specification.

TOP SEAL

Top Seals should be designed to maintain contact and limit water ingression when the door is in the closed and secured position. When the door is coiling, contact with the door surface will result in abrasion and, ultimately, damage to the surface. An effective Top Seal system should be able to provide a seal between the door curtain and the top gutter without damaging the door.

BOTTOM SEAL

The Bottom Seal should maintain continuous contact with the door sill when the door is closed.

INTERSLAT SEALS

Interslat Seals should prevent migration of moisture into the slat joint system and through the door curtain. They should also dampen vibration to help ensure quiet operation of the door when opening and closing, plus during travel.

Door Finishes

Roll-Up doors are typically available in 2 finishes:

- Anodized – an aluminum electro-coating process that results in a very hard surface.

This is the most cost-effective finish that prevents surface oxidation of the aluminum. Anodized is available in a “satin” finish – the most common and most economical – and in brushed” finish. Brushed anodized is often most expensive but can provide the added advantage of making minor surface damage less obvious as the door ages.

- Wet Paint – a multi-stage process that allows the doors to be painted to match the apparatus body or painted a contrasting color.

If Wet Paint is the choice, it is critical to understand the type of finish process that will be used. Most common is a multi-stage paint process involving a combination of some or all of: prime coat, base coat and clear coat.

Door Finishes (Continued)

When electing to use a Wet Paint finish, it is important to acknowledge that the paint will wear in areas where there is contact with seals or other components/surfaces. Over time, the wear will ultimately cut through the paint. As mentioned above, secondary steps may prevent or minimize the wear. These steps may be discussed with the apparatus manufacturer during the specification process.

In transverse compartment applications – where one large compartment spans the width of the apparatus with doors on both sides – the interior surfaces of the doors will be visible. This can result in some amount of paint overspray being exposed and visible. Most door manufacturers offer the option of pre-masking or taking precautions to reduce overspray.

Door Ajar Switches

Both NFPA Standards 1901 and1906 require that an audible and visual alarm be activated if a compartment door is not closed when the apparatus is in motion. The most common way to address this is with a “Door Ajar Switch”. The devices are available in two styles:

- Magnetic Door Ajar Switch

- Mechanical Door Ajar Switch

Both styles accomplish the same function of sensing if a door is not closed and sending a signal that can be used to activate the audible and visual alarms.

Regardless of the system selected, it is recommended that the Door Ajar Switch have at least 2 outputs and be capable of handling a combined total of 30 amps across the 2 outputs. The two outputs are important because one needs to connect to the audible and visual alarms and the second needs to be available to trigger the compartment lighting.

There are advantages and disadvantages to each style – and the main points of comparison are identified below.

Mechanical

Mechanical Door Ajar Switches use a mechanical device, typically a button switch, that is triggered by the physical presence of a portion of the latching system. The most common Mechanical system involves a button switch integrated into an external Lift Bar striker.

The advantages of a Mechanical system include the following:

- Simple and easy to inspect,

- Detects the physical presence of the latching component which helps ensure that the door is not only “closed” but is “latched closed”.

Magnetic

Magnetic Door Ajar switches use a magnet and a sensor to detect that the door is closed.

The advantages of a Magnetic system include the following:

- No moving pieces to wear out,

- Not susceptible to chemicals attacking the sensing device,

- Depending on the door manufacturer, the location of the magnets and sensors can be customized.

Integrated Compartment Lighting

NFPA Standards specify the required compartment lighting levels needed for safe and effective fire ground operations. Most roll-up door manufacturers offer compartment lighting systems that meet the standard and some offer integrated systems that fit into the Side Frames. The advantage to integral systems is that they typically take less space in the compartment, leaving more room for equipment and minimizing the chance of damage to the compartment lights when removing and storing contents.

Pull Straps

As roll-up doors become larger, especially taller, it becomes more difficult for some first responders to reach high enough to pull down on a door to close it. Pull Straps can be an effective feature to assist in pulling a door down easily and safely.

Pull Straps are available in a variety of styles and materials including webbing, cord and woven flexstraps.

Drip Trays

Roll-up doors coil up as they are opened and, since the exterior of the door curtain is on the outside of the coil, moisture on the door face may drip into the compartment. The best way to prevent moisture from damaging compartment contents is to specify the use of drip trays.

Drip Trays perform two functions:

- Collect moisture that falls from the exterior of the door curtain as it coils inside the compartment when the door is opened – and, optionally, direct the moisture to a drain point,

- Protect the door curtain from damage by compartment contents. This is especially useful when heavy, large or awkward objects (such as backboards) are being removed or returned to a compartment.

Drip Trays should be deep enough to collect moisture but shallow enough to minimize interference with useful compartment height.

Because Drip Trays need to be removed for major door maintenance, it is advisable that they be easy to remove and reinstall.

Closing Thoughts

Effective use of storage space is often a key factor in designing fire apparatus. The wide variety of sizes, weights and frequency of use for the tools and equipment stored in compartments makes it essential that the compartment configuration be carefully planned in advance.

One example is that backboards typically require a tall compartment with enough clear height to accommodate proper storage plus allow for easy removal and storage. A Drip Tray will protect the roll-up door from damage during removal and storage of the backboard but the Drip Tray occupies space. Therefore, the compartment configuration must allow enough room for both the backboard and the Drip Tray.

Effective use of storage space and effective operation of roll-up doors can benefit from well planned compartmentation. Refer to the FAMA Buyers’ Guide on Compartment Management for more information on how to best organize and secure tools and equipment.

Like any tool, roll-up doors require periodic maintenance. To ensure longer life and reliable operation, consult with the fire apparatus builder and the roll-up door manufacturer to determine maintenance requirements and then follow the appropriate schedule.