Tires

Introduction

All of us who own or have owned a car or pickup know tires are round and black, expensive and probably one of the least exciting components on the vehicle. The fact that tires operate day to day with little attention and few issues tends to make it easy to forget they are the only contact with the road. Tires are key in our ability to safely control our vehicle and to withstand the forces generated during operation such as braking, driveline torque and steering control. Selecting the right tire from all the tires available on the market is not easy and can be time consuming.

The purpose of this guide is to provide departments with basic knowledge to assist in selecting the optimum tires for your fire apparatus.

Contents

Overview

Applications – Tire manufacturers use different materials and rubber compounds to design tires for specific applications, those most applicable to fire apparatus are:

- Over the Road Long Haul

- Region and In City

- On/Off Road

Tread Designs – Improvements in tire wear and service can be achieved by using position specific tread designs and compounds within each of the above applications.

- All Position

- Drive

- Trailer

Few Emergency, Fire, or Rescue vehicles pull trailers so this guide will focus on All Position and Drive tread designs.

Tire Size – Your apparatus manufacturer considered factors such as gross axle weight rating, desired top speed, and vehicle performance when determining the correct tire size. Tire size must also be matched to the wheel rim diameter and width.

Load Capacity – The load capacity of the tires is determined by the tire manufacturer’s design but, is also dependent upon inflation pressure. The weight at each wheel position and manufacturer recommendations should be used to determine the correct inflation pressure.

Selecting Tires Begins with Vehicle Design

Selecting tires for your new vehicle will always start with the vehicle manufacturer recommendations. Based on the proposed vehicle design, they will provide a list of tires that:

- Meet or exceed the vehicle’s axle load ratings.

- Meet or exceed the vehicle’s speed requirements.

- Are available through supplier agreements.

- Comply with Federal, State and local regulations.

What Tire Will Work Best in My Application

Not all departments will have the same requirements. Some may cover large rural areas requiring the ability to travel long distances at higher speeds while others are composed entirely of urban operation. Here are several suggestions on how to find the tire that works for your application.

Previous Experience

If you are currently working on the spec for your department’s new vehicle, you have likely had some experience with tires. Did the tires meet your expectations? Were there any irregular wear or handling issues with the vehicles? If the current tires are working well and are available on the new vehicle design, you may want to stay with what you have.

Other Districts or Departments

Talking with other departments or trade show representatives can provide additional insight when evaluating your choices. If you can find a department whose area of operation is like yours and they like their tire’s performance, you may want to consider what they are using. Local tire dealers or OEM dealer representatives can also be useful for research.

Tire Manufacturer Data Books

Major tire manufacturers publish truck tire data books that are available for download on the internet. These data books include catalogs of available tire models as well as vocational tire information and recommendations.

TIRE APPLICATIONS

Tire manufacturers use different materials and rubber compounds to design tires for specific applications. Tires most well suited for emergency vehicles are:

- Line Haul

- Regional

- On/Off Road

Line Haul

The Line Haul application is made up of trucks operating primarily in common carrier and lease rental vocations. Vehicle annual mileage is typically between 80,000 to 200,000 miles. Attributes of tires designed for this application that can be beneficial for emergency vehicles include:

- Strong lateral adhesion

- Low Rolling Resistance

- Excellent wet and winter traction

On emergency vehicles watch out for fast wear due to turning, twisting and scrubbing.

Regional

The Regional application is made up of businesses such as public utilities, government – federal, state and local – food distribution, manufacturing, petroleum, and schools operation within a 300 mile radius. Vehicle annual mileage is usually between 30,000 and 80,000 miles. Tires designed for this application usually align well with the needs of Emergency vehicles. Attributes include:

- Tread compounds designed to better resist aggression, scrubbing and tearing.

- Improved mileage over line haul tires

On/Off Road

On/Off Road tires are designed to provide the durability and performance necessary in highly aggressive operating conditions at limited speeds. Vocations such as construction, mining and refuse use these highly specialized tires. Vehicle annual mileages average between 10,000 to 70,000 miles.

TREAD DESIGNS

Tread designs can be categorized in two basic groups.

Rib Tread Design

- Characterized by grooves placed parallel to the tire bead, thus forming ribs, ranging in tread depths from 11/32nds to 23/32nds.

- Usually significantly better for fuel economy, although does not provide enhanced wet or snow traction.

- Usually found on the steering axle and on other free rolling axles such as trailers, dollies, tag and pusher axles.

- Also placed on drive or torque axles when traction is not a high priority.

Block or Lug Tread Design

- Characterized by grooves placed laterally and perpendicular to the bead, more or less forming separate tread blocks ranging from 14/32nds to 33/32nds.

- Selected primarily for traction.

- Usually found on the drive or torque axle.

- The increased tread depth is needed to offset the scrubbing and/or spinning that can occur when power is transmitted to the drive axle.

Directional Tires

Truck tires featuring directional tread designs have arrows molded into the shoulder/edge of the outer ribs to indicate the intended direction of tire rotation. It is important, to maximize tire performance, that directional tires be mounted correctly on wheels to ensure that the directionality is respected when mounted on the vehicle.

Once directional tires are worn greater than 50%, there is generally no negative effect of running them in a direction opposite to the indicated direction of rotation.

Operating directional tires from new to 50% worn in the opposite direction of that indicated on the tire will result in the premature onset of irregular wear, excessive noise levels, and reduced tread life.

TIRE SIZE AND TECHNICAL SPECIFICATIONS

- TIRE SIZE: Radial truck tire sizes are designated by the nominal section width in inches or millimeters and the wheel diameter (e.g. 11R22.5 or 295/75R22.5). The “R” indicates a radial tire. Truck tire sizes contain dimension and load index information and are marked in accordance with industry standards: FMVSS (Federal Motor Vehicle Safety Standard), TRA (The Tire and Rim Association, Inc.), ETRTO (European Tyre and Rim Technical Organization), and the ISO (International Standardization Organization). Below are examples of tubeless tires.

Example: 11R22.5

11 = nominal cross section in inches

R = radial

22.5 = wheel diameter in inches

Example: 295/75R22.5 LRG

295 = nominal cross section in millimeters

75 = aspect ratio

R = radial

22.5 = wheel diameter in inches

LRG = Load Range “G”

TIRE SIZE AND TECHNICAL SPECIFICATIONS (Cont.)

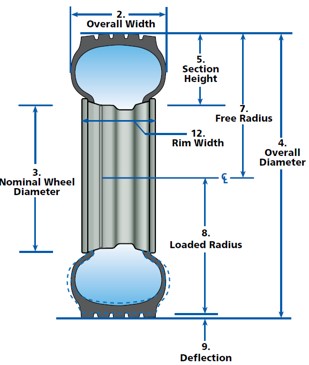

- Overall Width: The maximum width (cross section) of the unloaded tires including protruding side ribs and decorations.

- Nominal Wheel Diameter: Diameter of wheel seat supporting the tire bead given in nearest half-inch numbers, e.g. 22.5.

- Overall Diameter: The diameter of the unloaded new tire (measured from opposite outer tread surfaces).

- Section Height: The distance from wheel seat to outer tread surface of unloaded tire.

- Aspect Ratio: A nominal number, which represents the section height, divided by the section width and expressed as a percentage.

- Free Radius: One-half the overall diameter of the unloaded new tire.

- Loaded Radius: The distance from the wheel axle center line to the supporting surface under a tire properly inflated for its load according to the load and inflation tables found in the Tire Manufactures data books or on their web site.

- Tire Deflection: Free radius minus the loaded radius.

- Minimum Dual Spacing: The minimum allowable lateral distance from tire tread center line to tire tread center line in a dual wheel arrangement.

- Tire Revolutions per Mile: The number of revolutions the new tire will make in one mile. Data is normally presented for the loaded tire at its rated load and inflation in the drive position.

- Wheels: The approved/preferred wheels are designated for each tire size. The wheel shown first is the preferred wheel. Be sure to check wheel manufacturer’s specifications.

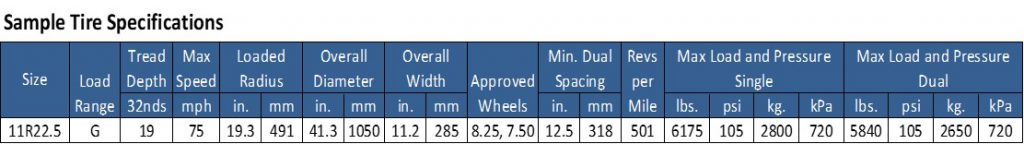

All the information required to determine the proper tire size can be found in the Tire Manufacturer’s data books or on their web site. A sample is shown below.

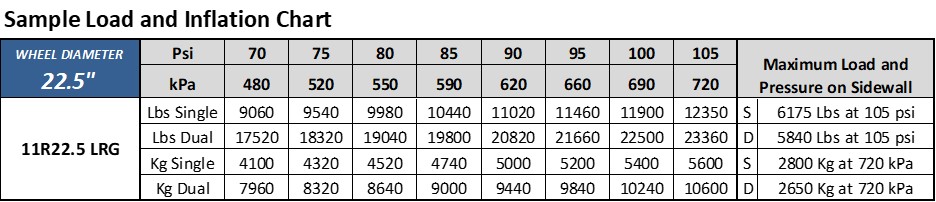

To select the proper tire size for a vehicle, it is necessary to know the maximum axle wheel end loads that the tires will carry and the maximum continuous speed at which they will operate. The maximum load that a tire can carry is different if it is mounted in dual configuration rather than single. The allowable axle loads and the required inflation pressures to carry these loads are shown in the charts for both single and dual mountings. The maximum allowable continuous speed is noted in the specification chart.

LOAD PER AXLE AND INFLATION PRESSURES

The carrying capacity of each tire size is tabulated for various inflation pressures by axle load for single applications (2 tires) and dual applications (4 tires). Due to the effects of load distribution and road inclination, the four tires in dual may not equally share the axle load. Therefore, to protect the tire carrying the largest share of the load, the capacity for dual applications is not twice the capacity for a single formation, but is usually between 5 and 13% less depending on tire size.

TIRE AND RIM ASSOCIATION INTERMITTENT EMERGENCY VEHICLE SERVICE PROVISION

The Tire and Rim Association Intermittent Emergency Vehicle Service provision provides guidance to tire manufacturers that allows for either increased loads of 7 percent above the tire’s rated load or an increase in speed. There is a limitation in distance traveled of 50 miles and the provision does not apply to all tire sizes. Tire manufactures have the final say on which of their tires qualify. Check with your vehicle manufacturer or tire manufacturer representative for more details.

Summary

There are many factors to consider when selecting tires including vehicle design, gross vehicle weight rating, tread wear, resistance to scrubbing, terrain, and previous experience. All must be considered to provide the best performance and lowest cost of operation. Your apparatus dealer can help you understand what tires are available in addition to the pros and cons of each option.