Scene Lighting

FAMA BUYER’S GUIDE TC037 Scene Lighting

Scene Lighting

Prepared by the FAMA Electrical Subcommittee

This guide does not endorse any manufacturer or product

Contents

Introduction

The NFPA 1901 Standard for Automotive Fire Apparatus does not specifically require the use of Scene Lighting on fire apparatus and makes minimal specific reference to requirements for apparatus that do incorporate the technology. Even though not required, Scene Lighting is an extremely popular choice for fire apparatus today and is explained a bit further in this Buyer’s Guide.

What is Scene Lighting?

In general, Scene Lighting refers to the system of lights and fixtures used to illuminate large areas of a scene such as a fire ground, vehicle accident or hazmat incident.

Typically, scene lights for fire trucks are in the size range equivalent of a 500w quartz fixture, or a 10,000 Lumen or larger LED fixture.

Scene Lighting can be broken down into a couple of application categories:

- Fixed Apparatus Mounted (Brow, Body, Tower, etc.)

- Adjustable apparatus mounted (on telescoping poles)

- Removable / Portable solutions (Tripods, generator-light kits, and battery powered solutions)

This guide describes many of the available technologies used on modern fire apparatus and can be used to help make an informed decision choosing whether or not to specify a Scene Lighting package on your next apparatus. This guide does NOT endorse any specific technology or manufacturer and is represented as general educational information only. For more information about specific technologies, it is recommended you contact a FAMA Member company with subject matter expertise. The Manufactures Guide can be found at www.fama.org.

Overview

Tasks performed by firefighters on fire scenes are inherently dangerous during the day. At night, the environment includes an additional level of risk due to the lack of light. Because of this, many fire departments opt to equip their apparatus with auxiliary Scene Lighting instruments designed to increase visibility and limit the risks associated with low light levels.

Today’s Scene Lighting technology can be broken down in to 3 categories:

- Halogen

- HID

- LED

Scene lights for fire trucks can be powered from either an AC “Line Voltage” electrical system, or a DC “Low Voltage” Electrical System.

Halogen Type Scene Lights:

- 500w, 750w, 1000w, and 1500w lamps common in fire service

- Pros:

- Lowest Cost Option

- Can be extremely bright

- Linear load, simple resistive circuit (good for generators, zero electrical noise)

- Cons:

- Short service life

- Impacted negatively by vibration

- High operating temperature

- Does not like water (thermal shock)

HID Scene Lights

- Typically, 35, 55, or 70 watts in automotive applications. 450 or 1000w in large “light plant” applications.

- Pros:

- Very efficient, much more efficient than Incandescent/halogen

- Can be extremely bright; think trailer-drawn light plants

- Typically, high color temp

- Median price point

- Cons:

- Takes time to warm up

- High inrush current

- Typically, no hot restrike

- Electrically noisy

- Limited parts supply

LED Scene Lights

- Pros:

- Extremely efficient

- Very versatile

- Small relative fixture size for comparable output

- Maintenance free operation

- No purchasing lamps

- Can produce as much or more light than other light sources; budget and physical size for thermal management are only limiting factors

- Cons:

- High up-front cost

- Complicated rating systems make them difficult to compare

- Electrical compatibility between AC fixtures and some generators can be troublesome

AC vs DC Scene Lights

Fire Apparatus often have two electrical systems; a 12v DC Chassis Electrical system, and a 120/240v AC Electrical System.

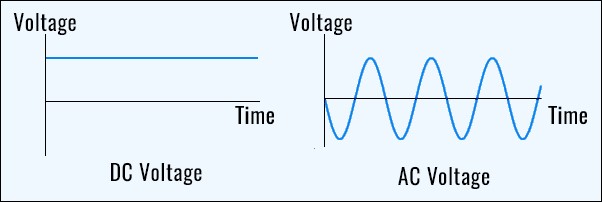

“DC” refers to “Direct Current” and means that the voltage is a constant. Typically, this is 12 volts DC on US fire apparatus. The DC electrical system relies on the Apparatus’ Engine to be running to charge the batteries, which in turn supply power for the items attached to them. DC electrical systems are covered in NFPA 1901 & 1906 Standards, Chapter 13, “Low Voltage Electrical Systems.”

“AC” refers to “Alternating Current” and means that the voltage cycles back and forth between positive and negative multiple times per second. Typical voltage peaks are 120v and 240v on US fire apparatus. AC Generators can be attached to the engine, or independent. Check out the Line Voltage Generators buyers guide (TC038) for more information about generators specifically. AC electrical systems are covered in NFPA 1901 & 1906 Standards Chapter 22, “Line Voltage Electrical Systems.”

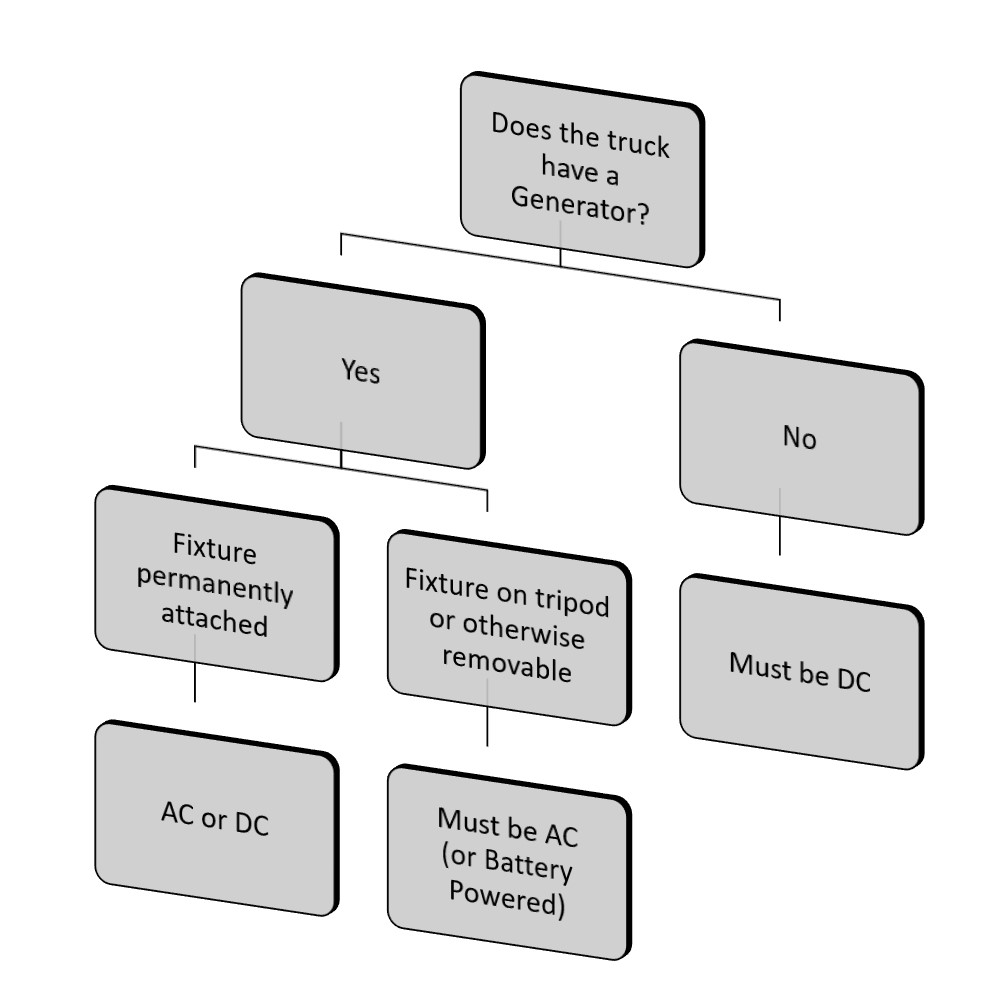

Regarding Scene Lighting for fire trucks, the biggest functional difference is that with a DC light, you are limited by the size of the conductor and the length of the run. As the distance increases, the amount of voltage loss increases more rapidly at a lower voltage. What this means is that virtually all Tripod and Portable lighting solutions that could be attached or removed from the apparatus should be specified as “AC” variants (unless they are battery powered).

Halogen vs LED

Halogen Lights:

With halogen fixtures, the lamp must match the voltage exactly. A 1,000w lamp designed for 240v AC will be dim and not work correctly if attached to 120v AC. Inversely, attaching a 120v lamp to a 240v Electrical system will overheat the lamp and cause immediate failure of the lamp [and possibly a fire].

Halogen Lights are typically offered in AC variants of 500w, 750w, 1000w, and 1500w.

It is common to find 12v DC halogen scene lights in 55-150w variants.

A halogen scene light never has the capacity to accept multiple voltages, the lamp MUST be matched to the voltage it is applied to (AC or DC).

LED Lights:

LED fixtures can typically be set up to operate on AC or DC voltage. LED fixtures produce more light with less energy required per lumen but, can still be manufactured such that they draw a significant amount of power.

LED scene light fixtures range in wattage from around 60 watts to well over 300 watts. Some manufacturers offer Multi-Volt fixtures; others operate similarly to the halogen fixtures mentioned above.

AC and DC LED scene lights are often offered in the same “wattage” configurations. The two most common wattage configurations are 75w and 150w which can roughly compare in usable light to a 500w and a 1000w quartz halogen fire-service fixture.

A common misconception is that “LEDs do not draw much power!” Watts are watts regardless what the load consists of. A 150 or 300 watt LED fixture is a very large load on a low voltage fire apparatus electrical system. It is important to remember that the Apparatus Manufacturer’s Sales Applications and Electrical Engineering teams must review any proposed light packages to ensure the electrical system on the rig can support it.

AC LED Lights- how to choose?

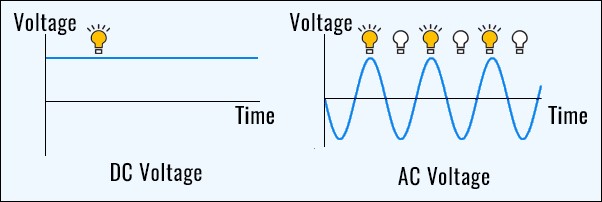

All LED chips themselves, operate on DC Voltage. An LED is very similar to a backflow preventer in a building’s water system: it allows electrons to flow freely in one direction (and emit light in the process) but stops the flow of electricity in the other direction. When you look at the graph below, the light bulbs indicate what would happen if an LED was attached directly to an AC circuit.

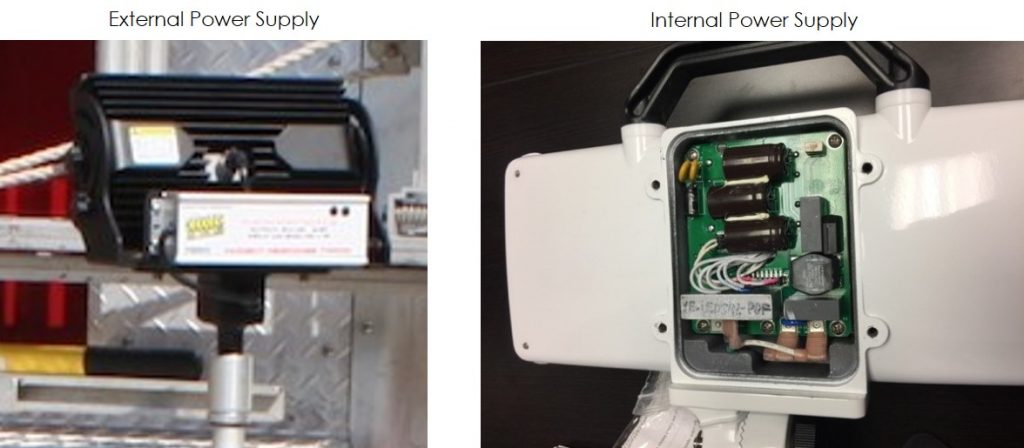

In order to use an LED fixture on AC power, a “power supply” must be used to convert the AC voltage in to a usable DC voltage for the drivers and the LEDs. This power supply can either be INTEGRATED directly inside the fixture, or it can be EXTERNALLY mounted on or near the fixture. Each manufacturer has a different approach to the method of converting AC power from the generator to DC power for the fixture. This power supply selection can have a profound effect on the performance of other components on the electrical system if not matched appropriately.

For more information about AC LED Light fixtures and the effect their power supplies have on the apparatus, check out this FAMA Forum Article here:

https://www.fama.org/forum_articles/apparatus-line-voltage-power-generation-high-tech-loads/

AC LED Lights, how to choose:

Use this flowchart to help decide between “AC” or “DC” fixtures

Scene Light Layout

When designing a lighting package for your rig, it is important to consider how the fixtures will be attached to the truck. The most important aspect of an effective scene lighting package is its ability to minimize the “highs and lows” in light levels on a fire scene. An even, clearly dispersed light pattern helps minimize crew fatigue and improve the overall visibility on the fire ground. The fewer highs and lows the better.

To accomplish this, it is generally a better practice to install a greater quantity of smaller fixtures around the truck than relying on a single ultra-high output fixture in one area on the rig to do all the work. Often the cost difference is negligible, and proper design offers a significant real-world advantage.

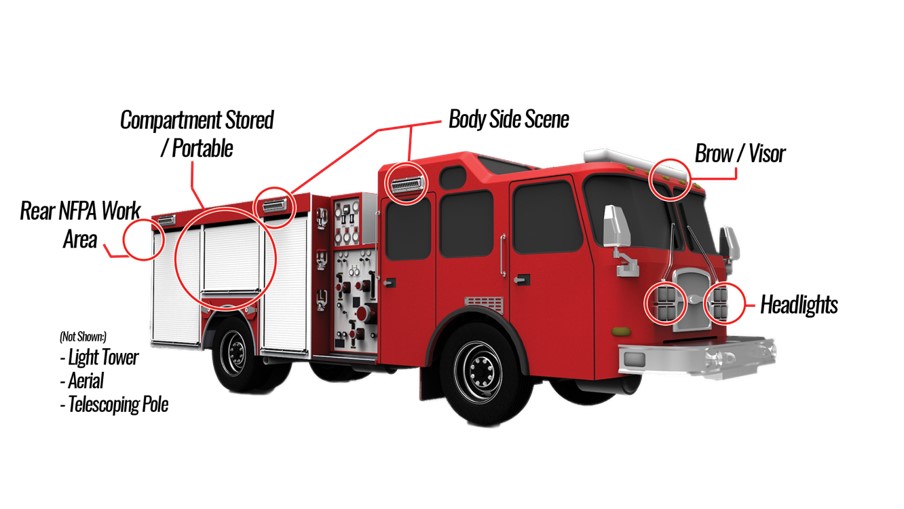

Areas of a fire apparatus typical for installation of scene lights:

- Fixed Apparatus Mounted (Brow, Body, etc.)

- Adjustable apparatus mounted (on telescoping poles)

- Removable / Portable solutions (tripods, generator-light kits, and battery powered solutions)

- Light Tower

- Aerial Device (ladder)

Mounting Continued:

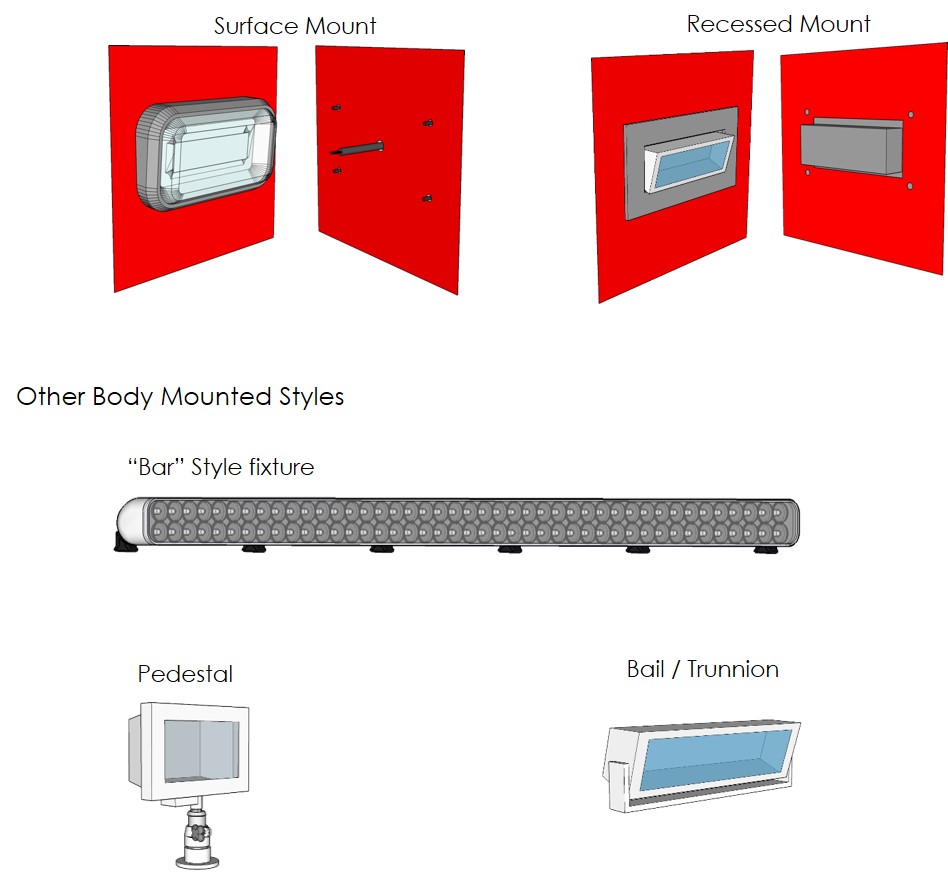

Below are some general examples of apparatus-mounted Scene Lighting options available from many FAMA member companies.

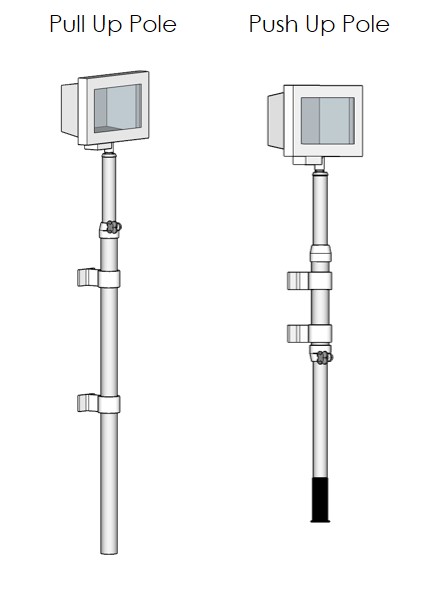

Telescoping Poles:

Great for getting lights up and away from the operators. Reduces glare and allows great flexibility for aiming.

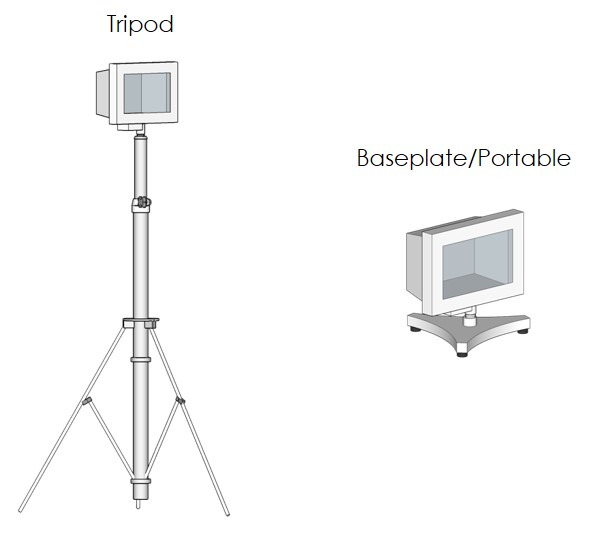

Tripod / Portable:

Used primarily for enhancing lighting in areas other than immediately next to the apparatus, such as around the back of a structure or inside during overhaul. Typically powered off of an AC Cord reel. Modern portables can be found in Battery powered configurations as well.

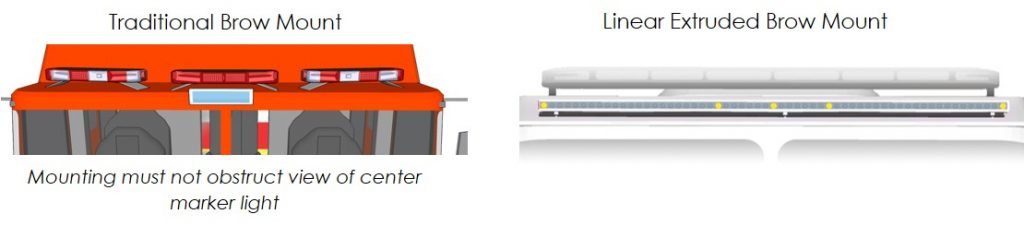

Brow Lights:

Light fixtures attached to the leading edge of the Fire Apparatus cab are often referred to as “Brow” or “Visor” lights. This type of fixture has become exceedingly popular over the last 3-5 years. Often it is used as immediate Scene Lighting that requires no setup or aiming.

Brow lights MUST be installed such that they do not obstruct the view of the FMVSS108 / DOT Clearance and Identification marker lamps. Some FAMA member companies offer linear extruded brow lights which incorporate these lamps in to their design.

A note about maintenance:

Virtually all light fixture mounts require some forethought regarding maintenance and operation. Light towers, telescoping poles, and portable fixtures all require periodic maintenance. Anywhere where a fixture has a moving part; pinned areas of light towers, clamping mechanisms or hardware on light fixture knuckles, telescoping mechanisms, and portable or tripod mounting parts, may require regular lubrication and/or cleaning. Refer to the manufacturer’s instructions for each part’s maintenance schedule.

Body Mounted:

Body mounted scene lights offer ease of setup and simple operation. Often times, the operator can switch these fixtures on from the cab. Body mounted scene lights typically come in two variants: “Surface” mounted, or “Recessed”

Surface mounted scene lights sit on the SURFACE of the body, and only require mounting holes and a passage for the wiring.

Recessed scene lights can be virtually flush with the outer sheet of the body, which reduces the protruding surface. Often this style is desired when departments are particularly concerned with branches or limbs coming in contact with the fixtures.

Where to Mount side scene lights?

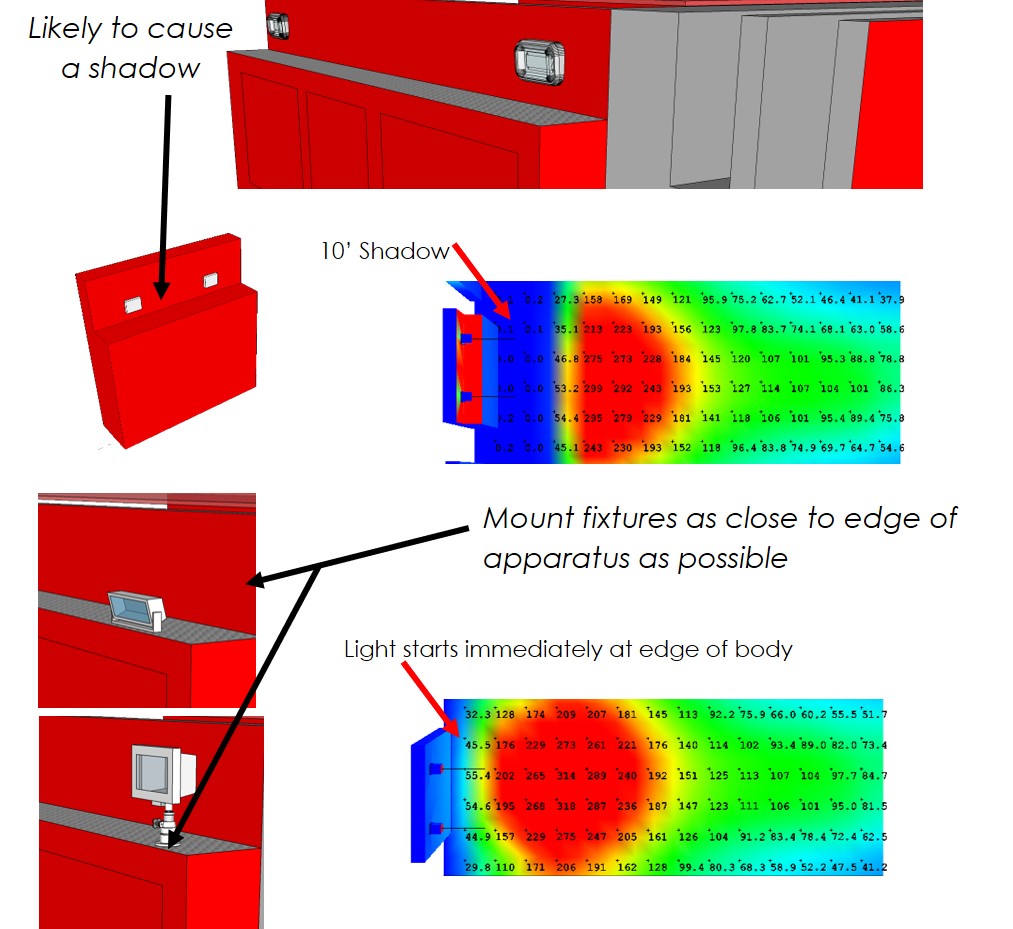

Choosing a mounting location is equally as important as the type of fixture. Often overlooked, on stepped sided bodies, mounting a surface or recessed scene light too far from the edge can cause undesired shadowing near the sides of the apparatus. On stepped side designs, consider a pedestal, trunnion, or bar style fixture mounted as close to the edge as possible to reduce the effect of shadowing.

Measuring Light Output. What’s required?

Fire market scene lights are often rated in “Lumen” outputs. It is important to note that NFPA 1901 DOES NOT require scene lights on a fire apparatus, and refers to most light output in Lux, or measured light on target, vs “lumens,” which is generally referred to as light at the source.

While Scene Lighting specifically is not required, NFPA 1901 DOES set guidelines for minimum light levels in areas on and near the apparatus. These minimums are outlined below (abbreviated) and can be found in the NFPA 1901 2016 edition Standard.

Ch. 13, Sec 10: Work Lighting

- 10.1.1.1 Rear of apparatus (10×10’ area). Avg 3 fc / 30 lux

- 10.1.2 Ground Lighting, area within 30” of edge of apparatus in area of ingress or egress from the apparatus. 2 fc / 20 lux

- 2.1 Hose bed. Average of 3 fc / 30 lux with all hose and dividers removed

- 10.3 Any work surface, stepping area, or walkway. 2 fc / 20 lux

Ch. 19, Sec 18: Aerial Safety (aerial tip lighting)

- 18.5 Lighting shall be provided to illuminate the aerial device in any position of operation (nonspecific light level)

- 18.6. Aerial Tip. Spotlight 75,000 beam cp OR a luminous flux of not less than 4,000 lumens

- see standard language for specific method of testing required for Luminous Flux measurement “lumens”

When not used in aerial tip lighting applications, each manufacturer uses their own interpretation of the best method to determine “lumen” outputs. Due to the variance in methodology for measuring light output, using Lumens alone is not a recommended method for comparing and contrasting fire market scene lights. Many FAMA member companies are willing to schedule an after-dark demonstration of their technology, and it is highly recommended to speak with each member company about their technologies directly.

A Firefighters Analogy: Lumens vs Lux (taken from Sept 2016 FAMA Forum Article)

Lumens

Lumens is the measurement of total comprehensive output from a light source. This measurement refers to light at the source—at the fixture itself—and does not help the user gain any sense of how well the fixture will illuminate the scene. It’s a “total power” type of rating and does not measure how much light is on the target.

The firefighting analogy for lumens would be measuring the flow of water directly at the nozzle without regard to pressure or pattern. A value of lumens will tell you how much light is leaving the fixture but nothing about how it is concentrated or dispersed.

Lux/Foot-Candles

Lux or foot-candles are two means to express the measurement of how much usable light is hitting what the fixture is aimed at. Lux is a metric measurement using units of lumens per square meter; foot-candles is expressed in lumens per square foot. Typically, because this is such a finite measurement, the measurement is coupled with an “area.” For instance, “Light A” will illuminate an area on the ground 30 feet away from the fixture that is 10-feet-wide by 10-feet-long to 50 lux. A fixture cannot be rated in lux like it can be in lumens because lux is measured on whatever surface the fixture is shining on, whereas lumens is measured at the source.

In firefighting terms, think of a handline flowing 250 gallons per minute (gpm) of water. If the appliance is an adjustable fog nozzle, changing the pattern from straight stream to fog does not change the gpm or flow rate, just the spread and direction of the water. Lumens can be equated to the gpm—the optics are the nozzle pattern, but the amount of water per square area hitting any given point is likened to the lux.

In straight-stream mode you can get either a lot of distance or a high intensity on something very close. When you open the pattern up, the fog pattern disperses that water into tiny droplets that cover a larger area with less intensity in any given location. In lighting, a spot light gives you a lot of intensity in a small area, or great reach, but by simply changing the optics to flood optics, you can disperse the light over a much broader area for more even overall scene lighting with less intensity at any given location.

For compete article, check out: https://www.fama.org/forum_articles/scene-lighting-firefighting-analogy/

Closing: Tips, tricks, and final considerations for scene lights for fire trucks

In conclusion, keep the following six summary points in mind:

- A well designed Scene Lighting package helps firefighters see after dark

- This includes on the apparatus, near the apparatus, and around the fire scene. Scene Lighting often includes various types of fixtures, using various types of mounts and often multiple electrical systems (AC, DC, and Battery Powered).

- A larger quantity of smaller fixtures placed more evenly around the apparatus often provides better overall work lighting due to minimizing the number of “highs” and “lows” on the fire scene.

- Halogen, HID, and LED scene lights all have relevant applications in the fire industry. It is okay to mix and match on your apparatus

- Don’t let your Scene Lighting package interfere with the FMVSS 108 Marker lights.

- Either mount the fixtures so that all marker lights are visible or integrate them in to the scene light.

- Schedule a demo! Many FAMA member companies have specially equipped demonstrative vehicles to help you make an informed decision about Scene Lighting.

- Lumens, lux, and light measurement are complex topics. Sometimes it helps to hold fixtures up side by side at night before finalizing your specs.

When finalizing your design, be sure to include the engineering department at your Fire Apparatus Manufacturer in conversations about voltage, amperage, and fixture selection. Your truck is like an ecosystem, small changes with scene lights can have a profound effect on the rest of the electrical system.