Front Suspension

Introduction

Front suspension systems are an important factor in the ride quality, equipment protection, vehicle handling/stability, and ongoing maintenance of a fire truck. When developing specifications for the front suspension on a fire apparatus, consideration should be given to handling, ride quality, chassis/equipment protection, initial cost, and total cost of ownership.

Contents

Overview

Ride quality is a function of wheel travel and the spring rate of the suspension. Ride quality is not only a benefit for vehicle occupants but can also provide protection for the vehicle and the equipment it carries.

Roll stiffness, wheel cut, and brake dive are other parameters to consider for vehicle design due to aggressive driving that may be required to arrive timely on a call.

Typical commercial chassis fire trucks will have capacities of 12,000lbs – 23,000lbs. Custom chassis fire trucks will typically offer higher capacities of 20,000lbs – 24,000lbs.

Wheel cut which is also referred to as cramp angle is the angle the front wheels can turn and is another consideration. A higher amount of wheel cut allows more maneuverability in tight locations such as city driving. The wheel cut along with the wheelbase will determine how tight the turning radius of the fire truck will be. Wheel cut of 40-55 degrees are typical.

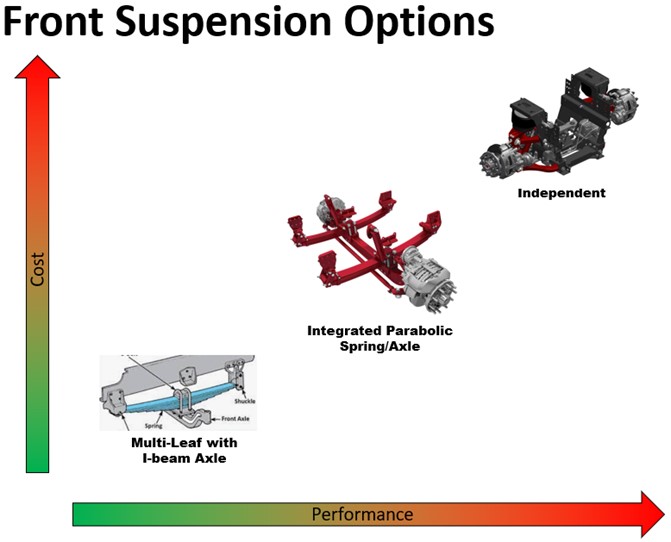

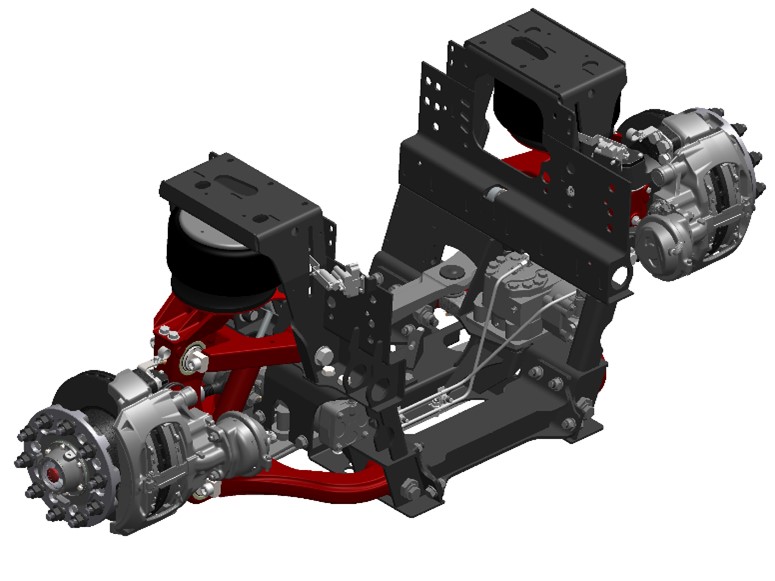

There are five primary methods of supporting the front suspension; multi-leaf spring, parabolic-taper leaf spring, air spring, coil spring, and torsion bar. These methods can be combined in two mechanical means, either a solid axle, or an Independent Front Suspension (IFS). This guide will provide a description, pros and cons, operating environment considerations, and capacity ranges for each suspension type.

Higher cost suspensions often result in better operating characteristics such as ride quality, roll stability, and wheel cut.

Multi-Leaf Spring Suspension

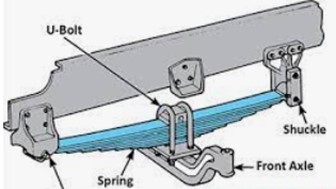

This system historically was the most common in fire apparatus so has the highest population in the field. A multi-leaf features multiple leaves and has a step-down effect with each leaf being progressively shorter than the one above it.

PROS OF MULTI-LEAF SPRING

- Low cost

- Readily available parts

- High roll stability

- Good serviceability

- Average amount of brake dive

CONS OF MULTI-LEAF SPRING

- Lowest ride quality

- Reduced equipment protection

- Load affects ride height and ride quality

- Requires load balancing to prevent vehicle lean

- High amounts of friction between leaves resulting in wear and corrosion resulting in lower overall durability

- Heavier than a parabolic spring

Parabolic Taper-Leaf Spring Suspension

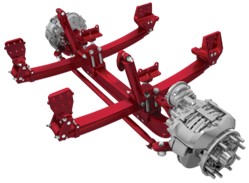

A parabolic taper-leaf spring suspension has fewer leaves and tapers at each end. The parabolic springs will have spacers to separate them so will typically only contact at the ends to reduce contact and friction between the leaves. This type of system is becoming the standard beam based front suspension in fire apparatus.

PROS OF PARABOLIC TAPER-LEAF SPRING

- Low cost

- Improved ride quality over a multi-leaf system

- Less friction between spring leaves so less wear/corrosion resulting in better overall durability

- Readily available parts

- Good serviceability

- Potential to be lower weight than multi-leaf

- 45 degrees of wheel cut at 24,000lbs is possible

CONS OF PARABOLIC TAPER-LEAF SPRING

- Reduced roll stability from a multi-leaf system

- Potential for a higher amounts of brake dive than multi-leaf

- Load affects ride height and ride quality

- Requires load balancing to prevent vehicle lean

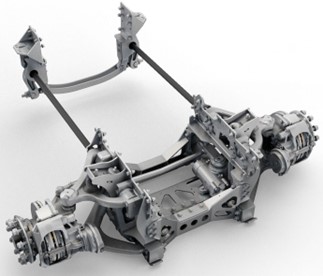

Independent Front Suspension (IFS) – Mechanical

IFS-Mechanical are available in the full carrying capacity range used by the fire truck industry.

PROS OF AN IFS – MECHANICAL

- Potential for the best ride quality with high amounts of wheel end travel

- Wheel ends react to road input independently – no crosstalk

- Excellent equipment protection

- Potential for minimum brake dive

- Potential for 40-45° wheel cut depending on capacity

CONS OF AN IFS – MECHANICAL

- High cost

- High weight

- More complex installation

- More connection points mean potential for more wear parts/maintenance

- May require more frequent re-alignment for camber and toe

Independent Front Suspension (IFS) – Air

IFS-Air are available in the full carrying capacity range used by the fire truck industry.

PROS OF AN IFS – AIR RIDE

- Potential for the best ride quality

- Wheel ends react to road input independently – no crosstalk

- Excellent equipment protection

- Similar ride quality when both loaded and empty

- Maintains constant ride height regardless of load

- Potential to reduce front body lean if dual valves are used on front air instead of rear

- Potential for minimum brake dive

- Potential for 50-55° wheel cut depending on capacity

CONS OF AN IFS – AIR RIDE

- High cost

- High weight

- Airbags are susceptible to damage or punctures

- More complex installation

- More connection points mean potential for more wear parts/maintenance

- May require more frequent re-alignment for camber and toe

Suspension Capacity

Departments should select the correct capacity rated products. Selecting higher capacity ratings does not increase vehicle durability, it can decrease the life of chassis/body/equipment. It can also decrease ride quality resulting in driver fatigue, lower resistance to rollover, and negatively impact handling.

Suspension capacities for steer axles range from 12,000lbs to 24,000lbs. It is highly recommended to use the FAMA Fire Apparatus Equipment Weight and Cube Calculator (TC018) to help determine how much carrying capacity you will need for the front and rear suspensions.

Other Considerations

If you are considering a new type of front suspension or supplier on your next apparatus purchase it is recommended that you reach out to other local fire stations that have a similar apparatus. Getting their feedback on vehicle ride quality and handling along with the supplier’s level of support can help ensure a proper specification. Organizing an onsite review and ride and drive is also encouraged.

Summary

While initial cost of ownership may be higher for certain systems, departments should consider overall total cost of ownership which includes maintenance, ease of service, and wear and tear from reduced ride quality. With the inclusion of more sensitive electronic equipment, reduction in vibration becomes even more important.